Nebraska’s Construction employment is predicted to continue growing over the next couple of years, according to the latest long-term economic forecast from the Bureau of Business Research at the University of Nebraska-Lincoln. Construction is expected to be the fastest-growing sector of the state’s economy through 2018.

Central Community College in Nebraska developed a heavy equipment operator training program that can take training on the road.

The demand for equipment operators outnumbers the supply, and the state’s companies are feeling the pain. Several construction companies approached Central Community College in Nebraska about creating a heavy equipment operator training program. New operators were coming to them without the proper skillset. All parties agreed that an operator training program was essential to the future of the building trades and the state’s well-being.

Three construction-related associations donated $1 million to set up and launch the program – the first of its kind in Nebraska – in August 2016. Matt McCann was hired as the Program Director and Jason Baker as the Instructor, each with a background in construction and demolition, respectively.

A blended learning approach shapes the college’s heavy equipment program. The one-year diploma program which leads to an optional two-year degree features a combination of classroom time studying such subjects as equipment operations, critical thinking, problem solving, and site operations—where students learn how to use GPS, simulation training, and on-the-iron experience. The second year features a summer internship and classes such as workplace professionalism, communications, project management, and of course, more heavy equipment operations training. The school owns between six and eight acres that is used as a practice arena. Once the students hit a certain level of proficiency they move to the outdoor lab for on-the-iron training.

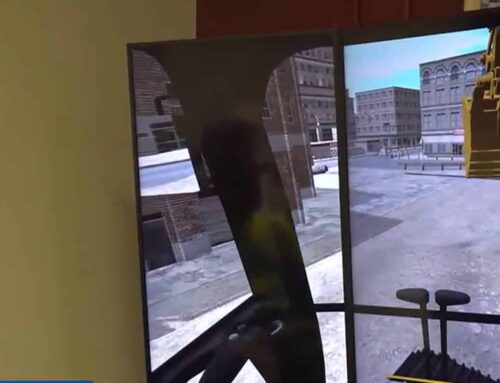

During the planning for the initial program, McCann and Baker knew that simulators were going to play an essential role. Two simulators were donated to the program and three more were purchased. An Articulated Truck, Dozer, Hydraulic Excavator, Large Wheel Loader and Motor Grader, all outfitted with a motion system, were integrated into the curriculum. “I’m impressed with how life-like the motion system is. I felt like I was on the actual machine,” says McCann.

The safe environment was a selling point as well. “When Matt and I learned heavy equipment operation, we were thrown on a machine and told to figure it all out,” says Baker. “Safety is a priority we set for the students. In a real machine, the students could hurt someone, hurt themselves, or cause damage to the machine,” he adds. The simulators remove that risk. Any mishaps happen in the simulated environment.

Classroom instruction allows students to train in a safe environment and get feedback from instructors.

Baker knows firsthand what can go wrong when even experienced operators become complacent about safety. With his background in demolition, he has experienced operators that have been hurt, or worse, because of complacency. Baker stresses safety throughout his training to drill good behaviors into students. The simulator can be used for training many types of safety scenarios. For example, understanding tipping points on the machine. The motion system allows users to feel movement and vibration, just like on the real machines, so when they are operating the simulated machine on a slope they can feel any unstable ground that might cause them to tip.

Students not only meet safety standards, they also meet other stringent policies in class. In addition to machine operation, they are graded on attendance, effort, and also placed in a random drug testing pool—just like they would be in the real world.

Central Community College teaches heavy equipment operation with emphasis on safety. Training on Cat® Simulators helps students achieve safety standards.

The learning process doesn’t stop after class is over for the day. The students are advised that anytime they want to get on a simulator to practice they may do so. Several students have taken advantage of that offer. They agree that the M-Series Motor Grader is the most challenging machine to learn. The Grader simulator has made the students more comfortable with operations. Students have spent extra time on the simulator to perfect their skills and learn about operation techniques before getting back on the actual machine.

To help promote the program, Baker and McCann have taken simulators on the road. The school outfitted a Sprinter van so they can take two simulators and travel to career fairs and other events. Future students can try out the simulators and learn about the heavy equipment program. The simulators are a great recruiting tool, getting attention wherever they go!

Having a classroom full of students itching to get on the iron, Baker has found a clever way to encourage his students to do their best. As excited as they are to get on the machines, students have to earn—and learn—the right to do so. Students have to dig in, literally! All Baker’s students get a shovel at the beginning of class. They must use the shovel until they are proficient enough to handle the machinery. It’s a creative way to make sure students put safety and practice first.

The school is at no loss for new students. Classes are filling up with eager learners. Ages range from right out of high school, to mid-thirties, to students beyond retirement age who believe in life-long learning. Good news for local companies ready to hire as soon as they finish the program.