In This Issue

- Hubbard Construction Company’s Zero Carbon Footprint Journey

- New Cat® Simulators Next Generation Excavator System

- High-Tech Protective Gear Infographic

- Cat Simulators Advanced Dozer System Video

Hubbard Construction Company’s Zero Carbon Footprint Journey

Based in Florida, Hubbard Construction Company has more than 105 years of experience in infrastructure and is committed to helping its parent company, Vinci, reduce its carbon footprint across 60 countries by 2030.

To help meet the zero-carbon goal, Hubbard changed how it trains its workers, operates its equipment, and measures success in the United States. “Sustainability starts at the ground level—literally,” said Andrew Miller, training manager for Hubbard. “Traditional operator training relies heavily on real equipment, and that means burning thousands of gallons of diesel before a single job even begins.”

Hubbard flipped the training model by integrating Cat® Simulators systems into its programs.

“We run training programs for every type of equipment we use. It’s a blend of theory and hands-on practice. Trainees start on the simulator in a controlled, safe environment, then transition to real machinery. Only after they train on the simulators do they work on active jobsites, like highways,” said Miller.

After monitoring the company’s carbon footprint for four years, the results have been substantial. By replacing a significant portion of its heavy equipment operator training with simulator training, Hubbard has achieved:

- 4,000+ gallons of diesel saved annually

- 1,200 metric tons of CO₂ emissions avoided—equivalent to removing 260 passenger vehicles from the road for a year

- 30% increase in fuel efficiency among simulator-trained operators

- Reduced wear and tear, extending equipment life and lowering embodied carbon

Learn more about Hubbard Construction and the results the company is achieving by training operators using Cat Simulators.

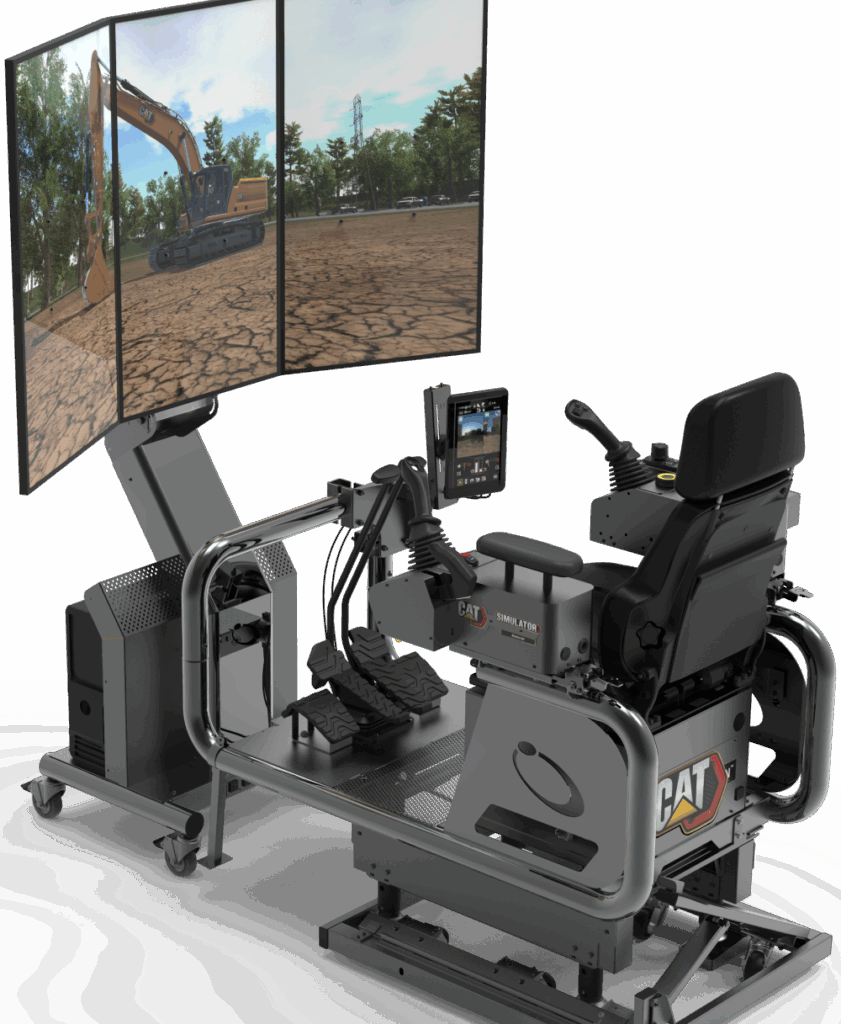

New Cat® Simulators Next Generation Excavator System

We are excited to announce the release of the new Cat® Simulators Next Generation Excavator System. The new simulator system teaches learners to operate an excavator more efficiently and effectively when utilizing Cat® Technology systems.

Set in a realistic city construction environment, learners gain experience through hands-on training exercises that include trenching with Cat Swing Assist, bench loading with Cat Payload, setting trench depth with Cat 2D Grade with Assist, and more. The system also includes a replica in-cab monitor that mirrors the monitor on an actual machine and operates in real time with the simulator.

“The new Next Generation Excavator system levels up the Cat Simulators family of excavator models,” said Vanessa Price, Vice President of Simformotion. “The simulator’s exercises focus on training learners to use Cat Technology systems that are integrated in today’s equipment. Our team worked closely with Caterpillar’s experts to develop each exercise, ensuring that all learners—whether they are new or experienced heavy equipment operators—can efficiently, effectively, and accurately utilize the technologies to operate the machines.”

Contact us to learn how you can integrate the Cat Simulators Next Generation Excavator System into your heavy equipment program.

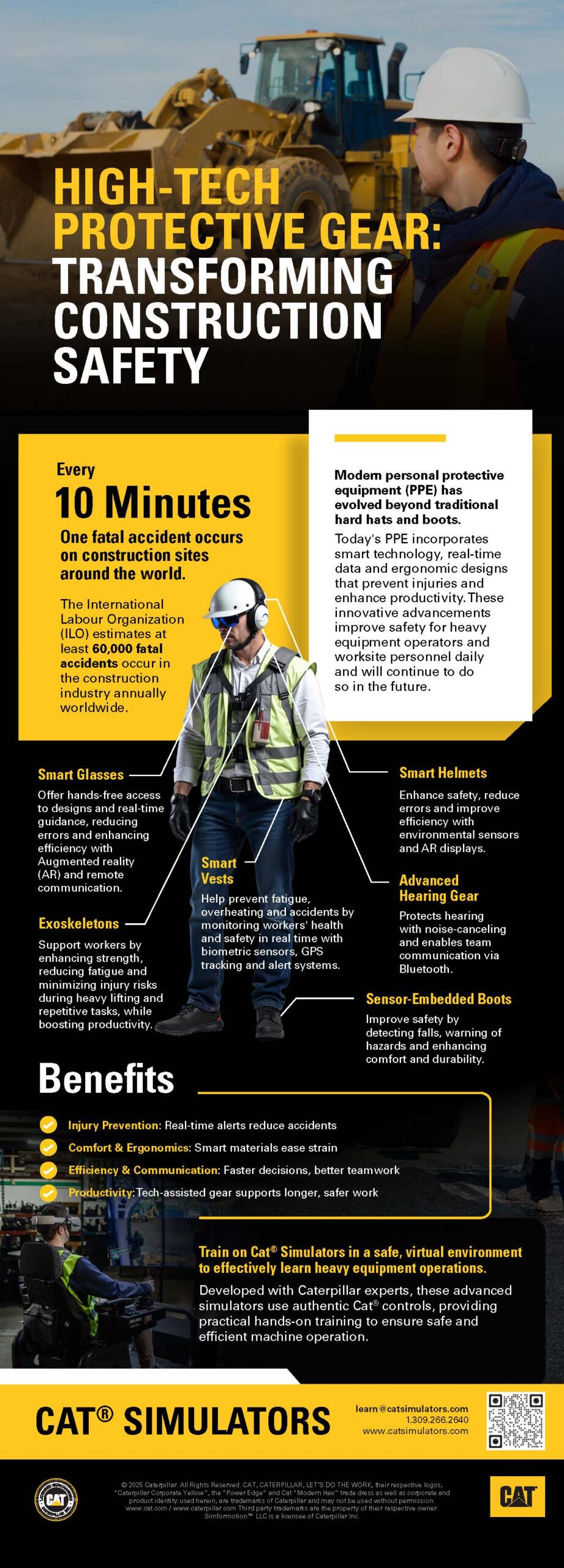

High-Tech Protective Gear: Transforming Construction Safety

Modern personal protective equipment (PPE) has evolved significantly beyond just hard hats. Today’s PPE incorporates smart technology, real-time data, and ergonomic design to improve safety and efficiency for heavy equipment operators and worksite personnel. This trend of innovation is expected to continue.

Download our free infographic to learn more about today’s PPE and how it’s transforming construction site safety for all jobsite workers.

Contact us to learn how to add Cat Simulators systems to your training program.

Cat® Simulators Advanced Dozer System Video

Tom Brodnax, high school heavy equipment instructor, shares how teaching his students to operate a Dozer with the Cat® Simulators Advanced Dozer Simulator System prepares them for the real machine and workforce.

“What’s amazing is that the controls they’re using are so realistic to them when they sit in a real machine,” says Brodnax. “When you see them [students] every semester, get into the capstone final exam, where they’re on the full-size iron, it brings goosebumps to you because you’re watching 14, 15, 16-year-old kids, and they look really proficient. I owe that to the simulators.”

Watch the video to learn more about the system’s features, including authentic Cat® controls, numerous training applications, motion control and much more.