An important responsibility for any heavy equipment operator is conducting a machine inspection. To ensure the operator’s safety and that of other job site personnel, and to make sure the machine is in good operating condition, the operator should conduct a walkaround inspection of the machine before beginning operation. Walkaround inspections take only a few minutes, yet they are one of the best ways to prevent maintenance problems and discover any safety hazards. For example, when the operator finds a fluid leak, a loose hose fitting or some other problem before a failure, injuries can be avoided and repair time minimized.

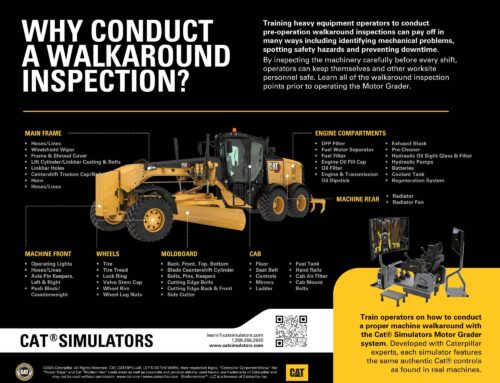

Each piece of machinery is different and therefore will have different parts that need to be checked during a walkaround inspection. The operator should refer to the Operation & Maintenance Manual for diagrams and information on the particular machine being inspected. Operators should use their senses of sight, smell, sound and touch.

- Check the machine before beginning a shift and again at the end of the shift.

- Make sure to conduct the inspection the same direction every time.

- If anything is different on the machine from the way it was when the operator started that day, the information should be passed along the next operator and this detail placed on the shift report.

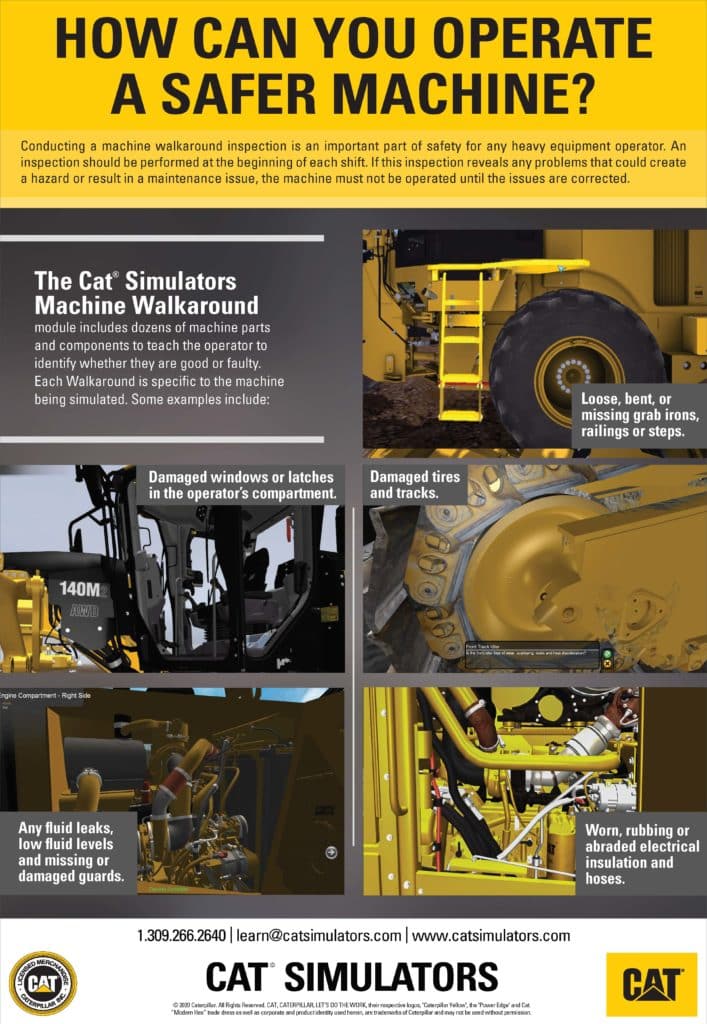

Making safety a priority begins with operator education and training. Using Cat Simulators as part of an overall training program is an excellent way to focus on safety. Cat Simulators include a Machine Walkaround featuring dozens of fault points to train and test the operator before he runs the actual equipment. Operators can learn proper procedures and good habits from simulator training and ensure the safety of personnel and machines on the job site.

Take a look at the Infographic to better understand the benefits of the Cat Simulators Walkaround. Contact a Cat Simulators Account Manager today or call us at 1.309.266.2640 and find out how to integrate simulator training into your organization.