Avoid unplanned maintenance on your Mining Truck by practicing correct operating procedures. Haul trucks will stay in production longer with proper use, including conducting a pre-operation machine walkaround inspection before every shift. Regularly scheduled maintenance checks, along with these tips, will achieve maximum uptime from your Mining Truck.

- Know the load limits for the truck. Do not overload. Check the Operation and Maintenance Manual for details.

- Avoid applying the brakes excessively on steep inclines. Use the automatic retarder control.

- Periodically watch the brake oil temperature during the descent. Too much speed will build up heat quickly and can shorten brake component life.

- Choose tires to match the terrain and jobsite conditions. Size and width can affect performance and lifespan.

- Do not overload trucks. Disregarding load ratings can affect the life of tires and brake systems.

- Early tire wear or failure can be caused by running over rocks and debris. This is another reason to avoid overloading the bed and causing spillage.

- Center the load correctly in the truck bed or the truck could suffer wear or damage.

- If the load is shifted to the front, wear or damage occurs to the front brakes, bearings, front tires, steering, hydraulic hoist or body canopy. The truck may not dump properly.

- If the load is shifted to the rear, the final drive and rear tire could suffer wear or damage. The payload will become unstable and spill off the back.

- If the load is shifted to the side, wear or damage can occur to the final drive, bearings, hoist cylinders and pivot bore areas.

- Do not let stuck material build up in the truck bed. Debris can cause corrosion and shorten the lifespan of components.

- When approaching the dump area, slow down before turning to help prevent the front tires from rolling over to the side and causing excessive premature tire wear.

- Identify and consider overhead obstacles when driving the mine site or approaching and unloading at a crushing facility. Lower the truck bed down completely before exiting the unloading area.

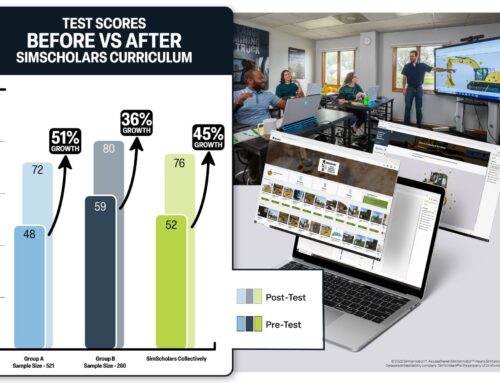

Cat® Simulators can train operators how to perform a machine inspection and perform applications while in the safety of a virtual environment using authentic Cat controls. Operators who learn correct techniques before moving to the iron can help organizations save costs throughout the machine’s life.

Contact us for a demo.