Extend the life of Articulated Trucks with proper operation and maintenance. Include a pre-operation machine inspection before every shift. Schedule maintenance checks and follow these tips to achieve maximum uptime for Articulated Trucks.

- Do not load the body with oversized material that can become lodged in the body or is unable to clear the end of the body.

- Know the load limits for the truck. Do not overload.

- Keep an eye on brake temperature, especially when choosing gears. If the brake temperature is too high, shift down to a lower gear and slow the machine down.

- Do not use excessive speeds, especially while under load. The additional weight and momentum are harder to stop and can lead to tipping and unplanned maintenance.

- Keep the Truck straight and level when loading. These actions are beneficial in several ways:

- The required effort to pull away is reduced.

- The possibility of tire damage is reduced.

- Loading a Truck evenly will prevent uneven loading and wear on tires and axles.

- Choose tires to match the terrain and jobsite conditions. Size and width can affect performance and lifespan.

- Do not overload trucks. Disregarding load ratings can affect the life of tires and brake systems.

- When approaching the dump area, slow down before turning to help prevent the front tires from rolling over to the side and causing excessive premature tire wear.

- Check the machine’s Operations & Maintenance Manual (OMM) for alignment and grease schedules. The oscillation portion must be readjusted at given intervals to retain the proper specifications or the risk of the oscillation bearings, seals and retention system can be damaged.

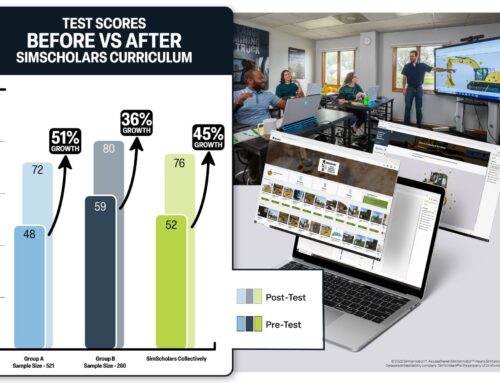

Teach operators how to perform a machine inspection as part of regular preventative maintenance with Cat® Simulators. Learners can make mistakes in the safety of a virtual environment without harming themselves or the Truck. When learners understand machine applications before moving to the iron, they can help organizations save costs throughout the life of the machine.