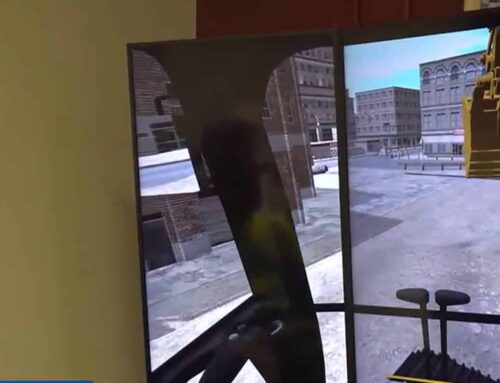

When Hoopaugh Grading Company, LLC, (HGC), one of the largest general contractors in North and South Carolina, opened the doors to the HGC Academy, owner Brian McManus’ vision became a reality. McManus and company leaders envisioned HGC would one day be a teaching company able to train and develop its employees to become some of the construction industry’s best. Located in a 20,000 square foot facility, the HGC Academy can accommodate over 100 students simultaneously in its three large training rooms, while rotating students on three state-of-the-art, customizable Cat® Simulators systems.

“We take a holistic approach to training,” explained Katie Page, HGC Director of Team Development. “In addition to our in-class curriculum, our certified trainers work with our teammates on the simulators then follow them out to the field. It’s more than just sitting in the classroom and learning. Our teammates have the opportunity to learn in different settings and environments.”

Page described the company’s growth of more than 200 new employees in 18 months as “quick growth.” She continued, “We’ve brought in some new teammates who have no experience in the industry. And part of the reason we could do that is the Cat simulators, along with our experienced field trainers in the Academy.”

“Bringing in this younger generation, especially those who aren’t considering going to college, or maybe are at a trade or technical school, is something we’re proud of,” explained Page. “It’s allowed us to be able to partner with local nonprofits and schools to help promote the industry and show people there’s a path besides college they can come into and still have a great career.”

Twenty-year-old Salma Limon was among those 200 new employees. Limon worked in a local food factory before HGC hired her in January as a compact roller operator. As a little girl, Limon never imagined being a heavy equipment operator although she had always enjoyed tagging along to jobsites with her dad. “One day I was sitting in a mini excavator when my dad teased me saying, ‘Don’t dig us to China!’” laughed Limon. “Now, 10 years later I’m out here working on construction sites operating a Caterpillar dozer.”

When Limon’s supervisor suggested she consider operating a dozer, Limon used the HGC Academy as a resource. She received in-class instruction and hands-on Cat Simulator dozer training to give her more experience on the dozer and to better understand the controls and applications. The simulator training proved invaluable to her. “Learning how to position the blade on the simulator helped me know how to control the real dozer blade, which is very similar to the simulator,” Limon explained.

The simulator also helped calm her nerves. “At first, when I got in the dozer, I had sweaty hands and was shaking a bit,” she said. “I was afraid of the tilting, but the simulator helped with that too.”

Tony Newlin, HGC Simulator Coordinator and Instructor has seen students like Limon many times. “They come in and they’re nervous about operating a new and different machine, but they know they’re not going to hurt anything on the simulator,” he explained. “The simulator takes a lot of the nervousness away. So, when students get on the actual machines, they’ve had the whole experience with all the buttons and switches and can focus on their task and what they have to do on-site.”

“When a supervisor wants to enhance somebody’s career or put them on a different machine for a higher pay grade or to support a new team, they send them here to the Academy. We train them on the simulators, answer their questions and coach them to make sure they understand everything and feel comfortable,” said Newlin.

Newlin continued, “With our three Cat Simulator motion platforms and five machine convertible controls, I can swap out our articulated truck, dozer, motor grader, wheel loader and excavator simulators in just a matter of 20 minutes.”

“There’s a waitlist to use the simulators and the flexibility that the convertible controls bring has been key to managing that waitlist,” said Newlin. “We have so many teammates who want to experience and better themselves on the simulators. They challenge themselves and each other, so it becomes a competition. Who has the most loads? The bigger bucket size? It’s good camaraderie.”

HGC Academy purchased the Manager’s Workstation software which tracks and records students’ usage data in July 2020. In the past 14 months, HGC students have logged a total of 530 hours of seat time, consumed over 1,500 gallons of virtual fuel and driven over 935 virtual miles, noted Newlin. “We’ve had numerous teammates advance their careers through the simulators. It’s been such a positive experience all around.”