Competition is present from several sources when it comes to filling seats in your operator, management, or technician training programs. Students have many options for careers and training, so to generate interest or differentiate your program, add Cat® Simulators.

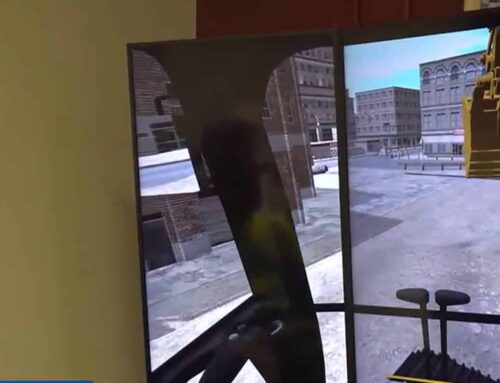

Simulator training has many benefits from safety to efficiency. Simulators can become an excellent differentiator for your school for those reasons and more. Making simulation a part of your curriculum can boost students’ skills so they can learn better and faster than traditional methods. Students use real controls and gain muscle memory that translates to the real machine. The training exercises feature the same applications as operators use on real-world worksites. In combination with theoretical classroom learning and hands-on in the iron practice, simulators can become a strong tool in your school’s curriculum.

“Students that come out of the program are better trained. It totally speeds up the learning process to use the simulators because when

[students] get on the actual machine they are not spending time trying to figure out what the controls do. Students already know which control to use to get the needed movement.”

Brian Badge

Chair of Trade, Northwest Community College in British ColumbiaHow can Simulators Differentiate your School?

- Safety first. Learning in a virtual environment ensures that students won’t hurt themselves, other students or the machines when learning operations.

- Expert operations. Cat Simulators training exercises are based on the same methods as Caterpillar expert operators use around the world. Each training exercise contains dozens of benchmarks so students know the level that they are to train to.

- Record & Report. Software records and reports the results of simulation sessions so you can find out which students pass or fail each training exercise. Review the results with students to discuss strengths and weaknesses and customize training for each individual. Students leave with a record of their training achievements.

- Future employment. Students learn the fine control movements needed to operate at optimum production levels. Potential employers can review the reports generated during simulation sessions to find out which students perform the best. Dave Hughes, Dean of Student Services, North Central Kansas Technical College (NCKTC), shares that contractors and employers visit the college and offer students from the heavy equipment program employment opportunities. NCKTC offers a high chance of placing students after completing their education. Skilled labor is always in demand. “When we use the simulators in the classroom, students go through all the lessons and must achieve a certain skill level.”

- Go mobile. The simulators can be easily mounted in a trailer or on a rolling platform to be transported to other campus locations for classes, demos or career fairs. In an example, Don Webb, Jr., PhD, Director, Kentucky Safety Training Institute says, “The simulators have traveled the country with us in our mobile simulator lab and have become an invaluable tool to our classes.”

- High tech. Play up the technology angle. Your school is forward-thinking and knows it’s important to integrate smart new technologies into its curriculum to draw in new students.

- Best press. Get press coverage when you use the simulators for demos to local and state officials. Showcase your school and your heavy equipment program. Feature the simulators at school open houses and invite students to operate them.

- On-demand. Train anytime regardless of weather. No need to cancel classes due to inclement weather.

- Multi-machine choices. Cross train multiple programs with simulators. More students can learn how to operate multiple types of machinery with simulators.

What if my school doesn’t have an operator program?

For schools that do not have a heavy equipment operator program, but do have a maintenance tech program, construction management or other heavy-equipment-related programs, the simulators also have a place. Featured simulation exercises like the Machine Walkaround teach students to identify parts of the machine and determine whether they are faulty or correctly working. Machine techs must be able to move the machines around the maintenance bays, so also need to learn how to operate them correctly. Construction and forest management students must also know basic operations in order to correctly estimate and schedule jobs.

Other Benefits

In addition to differentiating your school from the competition, there are many other benefits to integrating Cat Simulators into your heavy equipment program.

- One instructor can train multiple students on simulators. With traditional training, the costs of one-on-one training for the machinery must be budgeted. In a classroom setting, one instructor can oversee multiple students on simulators without concern of a mishap.

- Network the simulators together and review results from one workstation.

- Simulators do not burn fuel. Replace a portion of training with simulators and immediately reduce the fuel costs associated with training on actual machines.

- Reduced use of machines during class also means lower maintenance costs – no engine use, oil use or emissions with simulators. Replacing a few hours of in the iron training with simulators can make a big impact to the bottom line.

Integrate simulators into your curriculum and experience a rise in enrollment and a host of other benefits.