Heavy equipment operators use Cat® Simulators for blind spot awareness

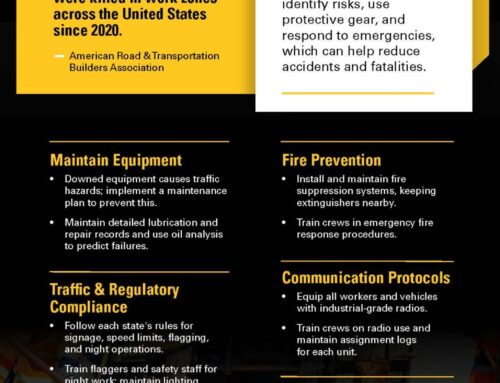

Heavy equipment operators inside a cab often have limited visibility and blind spots. A blind spot happens when the operator can’t see objects directly or with mirrors. Each machine has its blind spots, which can be dangerous for operators who can’t see nearby people or objects. Workers on the ground are especially at risk. By following safety practices, operators can help prevent “struck-by” accidents and keep themselves and others safe on the jobsite.

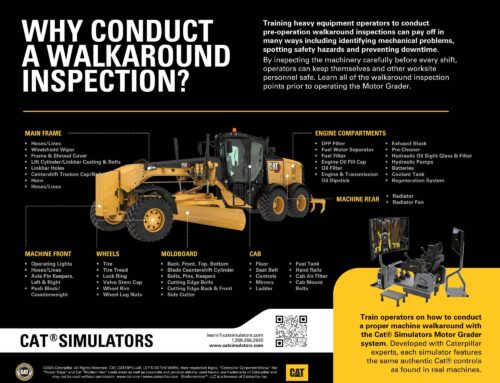

Download the free infographic and contact us to find out how Cat® Simulators can better train operators.