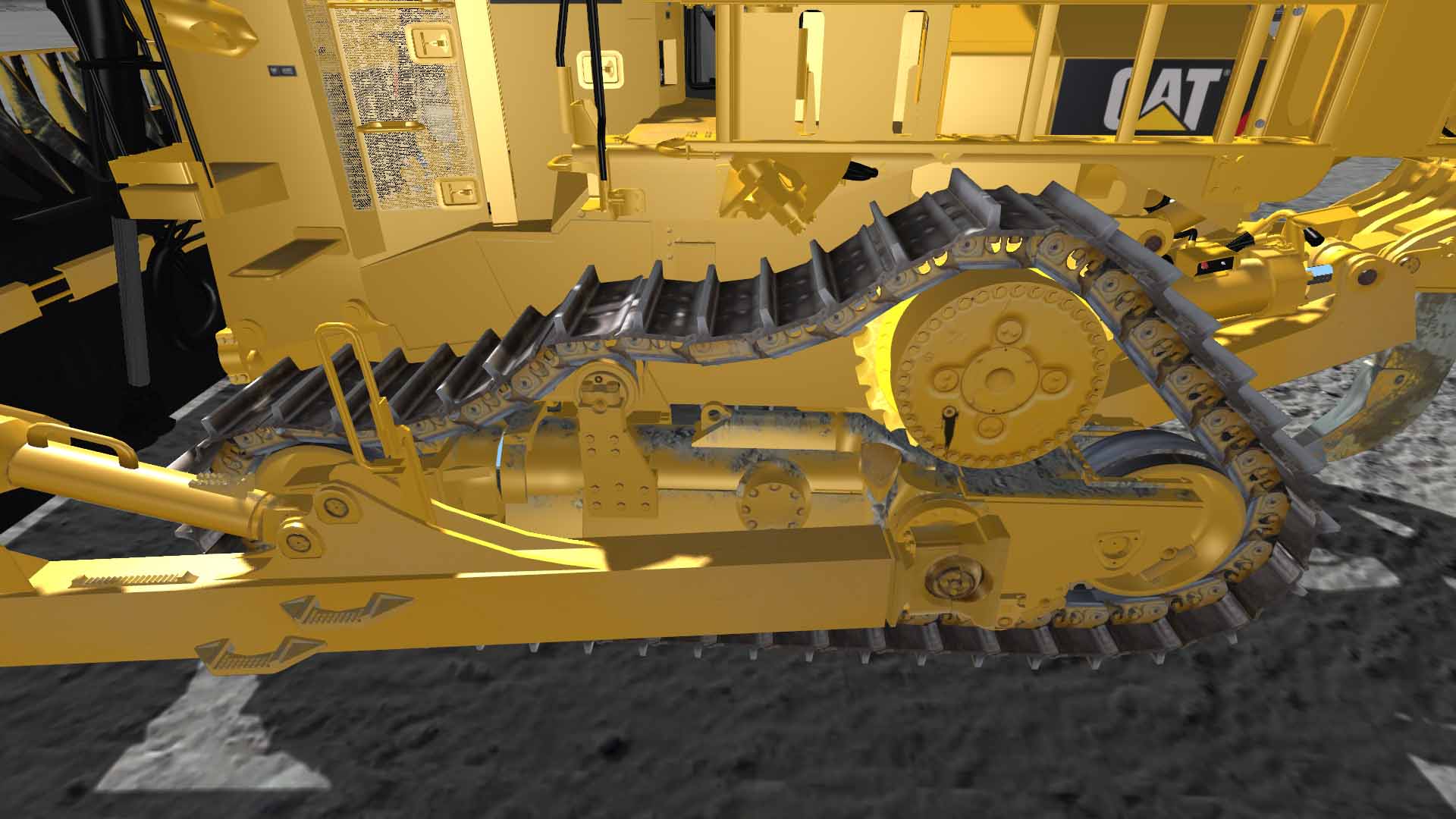

Cat Simulators are equipped with the same controls as the actual dozers; and training exercises that are the same ones used on real world worksites. Doug Bohnker, Installation and Training Instructor, shares his favorite tips to avoid damage to the undercarriage.

- Be aware of the terrain that the machine is traveling across. Do not run the machine with one track running along a windrow. This will transfer machine weight and stability to the other track, accelerating undercarriage wear.

- Throughout the overall life of the dozer, one half of all the maintenance cost can be spent on the upkeep of the undercarriage alone. Keeping the tracks properly tensioned is vital. Due to the design of the track system there is twice the amount of wear in the reverse direction than in the forward direction.

- Whenever possible, reducing either the reverse travel distance and/or speed can extend the undercarriage components’ life.

- Using the steering control function correctly will reduce track wear and damage to the undercarriage. Avoid making fast hard turns, as this will add stress to the tracks and undercarriage, and increase ground disturbance in the work area, creating hazards for other machines and personnel.

- Making three-point turns will reduce track wear and increase undercarriage life, also reducing premature part failure and unscheduled maintenance.

- Be aware of the material being dozed and hidden hazards within the material to avoid damage to the undercarriage. Maintenance can be greatly reduced through operator awareness.

- Using the blade tilt control function for steering corrections while under load will significantly reduce undercarriage damage and unscheduled maintenance.

- Shank angle is important. Adjust the shank angle in until the dozer feels pulled into or pinned to the ground. The tip will fracture the material and shatter it as the shank passes through. If the shank is too far back, the tip will drag across the rock, resulting in excessive wear. The rear of the dozer will rise, resulting in track spin and undercarriage wear, poor shank and tip life and reduced productivity.

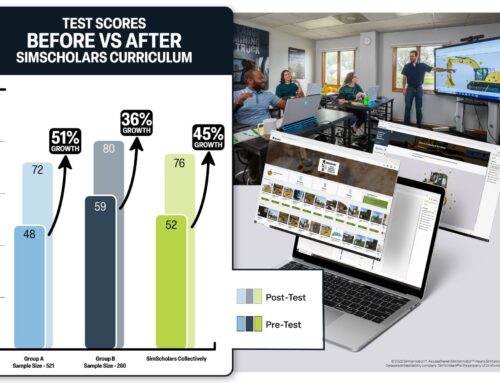

Unplanned maintenance costs will eat away at a project’s profit margins—and an undercarriage is the biggest replacement cost on the machine. Training operators on a simulator can help avoid unplanned maintenance costs and downtime. To find out more about training operators safely and effectively on the Cat Simulators Track Type Tractor and Mining Dozer systems contact an Account Manager at 1.309.266.2640 or email sales@catsimulators.com.