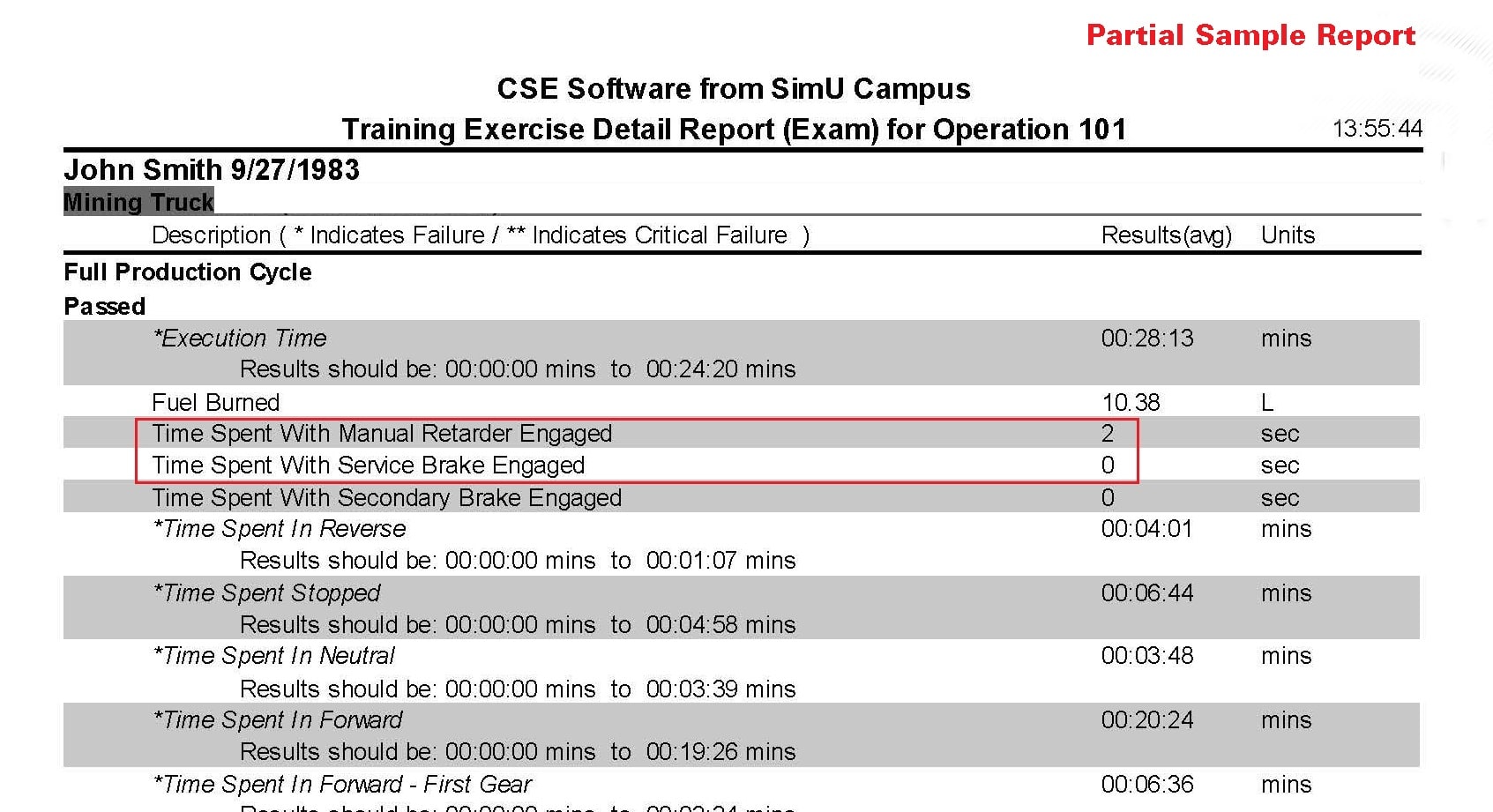

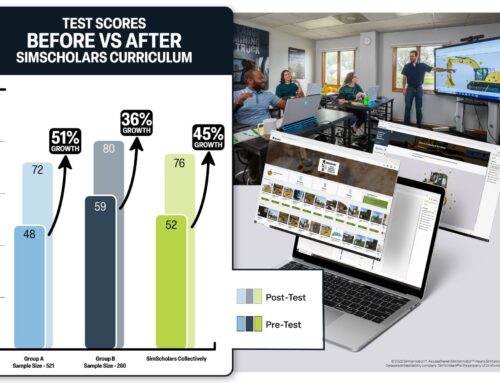

When choosing a simulator, it’s important to consider the method by which the simulator records and reports the results of user training sessions. The simulator should include robust software that tracks, measures and reports results based on benchmarks set within the simulator. Performance data allows instructors, training managers and HR to assess operator skill levels and identify any potential areas that could cause misuse of the machine or unplanned maintenance issues. Cat® Simulators reports hundreds of different benchmarks during training exercises. Here are a few examples and why it’s so important to report operator performance.

Proper Braking. An operator who does not use the clutch brake and instead uses the service brake when moving material causes a loss in productivity. The wheels are slipping and power is being lost to the hydraulic system when they are not using the proper brake.

Attack Angles. Attack Angles are the angles of the bucket with respect to the ground. Measuring that the operator is using the proper attack angle ensures that the operator is digging in an efficient pattern over and over and not getting sloppy with time, or with one pass compared to the next. Efficient digging patterns lead to optimum production levels.

Bucket Slams. Recording the number of bucket slams will help the operator fine tune his/her skills. Breaking hydraulic lines, due to bucket slams, can cause unplanned maintenance costs and time with the machine out of production.

Contact us with questions regarding training and records management software.