Avoid unplanned maintenance on your Backhoe Loader by practicing correct operating procedures. Backhoe Loaders will stay in production longer with proper use, including conducting a pre-operation machine inspection before every shift. Regularly scheduled maintenance checks, along with these tips, will achieve maximum uptime from your Backhoe Loader.

- Know the bucket’s load capacity and never exceed the limits. Overloading the machine can cause pins to bend or crack. See the Operations and Maintenance Manual for load limits.

- Do not use force, hit or compact material. Damage will occur to the bucket, stick and boom, and reduce machine life.

- Keep tires inflated to the proper pressure to reduce tire wear and improve stability. Over or under-inflation can reduce tire life.

- Do not shift gears too quickly as it can cause damage to the transmission.

- Do not lift an unbalanced load. This can lead to tipping which could cause the frame or boom to bend, crack or break. Plus, cause harm to the operator.

- Do not operate at excessive speeds. This can cause damage to the engine, transmission and hydraulic systems. It can also cause damage to the tires because of heat build-up that will lead to premature wear and eventual failure.

- Avoid working on rough terrain for extended periods of time. The impact of rocks, potholes and other obstacles can lead to damage to the backhoe loader’s frame, axles and wheels.

- Avoid wheel slip, which will lead to premature wear, by using the hoist and curl technique.

- Do not articulate the backhoe loader while loading a truck as it can lead to excessive stress on the boom, bucket and hydraulic system. It can also cause the load to become unstable, resulting in material shifting or falling off the bucket, causing harm to the operator or damage to the machine.

- Do not drop the bucket or boom suddenly as it can cause an increase in pressure on the cylinder and cause damage.

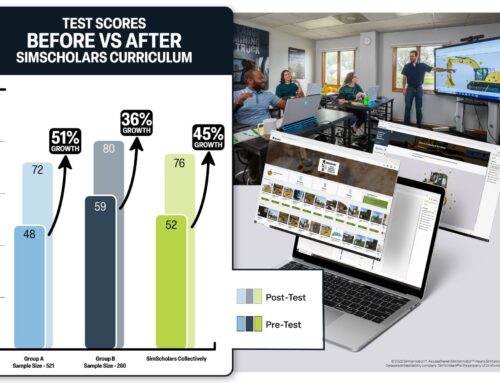

Cat® Simulators can train operators how to perform a machine inspection and applications in the safety of a virtual environment using authentic Cat controls. Operators who learn correct techniques before moving to the iron can help organizations save costs throughout the life of the machine.