The heavy equipment program at Keyano College is gaining traction around the region. At one time Keyano College, located in Alberta, Canada, had a busy heavy equipment program. The program was discontinued when the fuel and maintenance costs ran too high for the school’s budget. Administrators at the college remembered those days, but by 2014 knew the time had come to resurrect the program. A lack of skilled operators throughout the region was becoming an issue for local companies. When a team of instructors were asked what their biggest hurdle was, the first thing that came to mind was heavy equipment training. The group knew simulators were the answer.

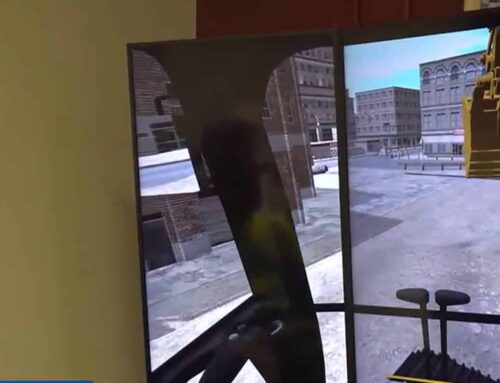

A short time later, the college administration found funding for a heavy equipment program. The team of instructors were ready to dig in and find the right simulators for the new and improved operator training program. Criteria included looking for something practical and easy-to-maneuver, but also mobile, so the simulators could travel throughout the region for training. With many simulator brands to choose from the team was determined to make the best choice for the college. Local company Aecon uses Cat® Simulators for training. The College administration arranged a visit to Aecon to see the simulators in action. Representatives from the college were impressed with what they saw and discovered that Simformotion™ was the manufacturer and licensee of Cat Simulators for Caterpillar.

However, due diligence was in order and the administrators and instructors did their homework. They vetted many simulator companies, from generic built to large container style simulators, before determining that Cat Simulators met all of their needs and offered the best value for the money. Cat Simulators won them over with two exclusive offerings: its motion and SimU Campus™ training records management systems. The ability to deliver a motion experience; and measure, record and report the results of student simulation sessions appealed to Instructors in a way that no other simulator system could. Reliability and mobility were the next two most important purchase points when choosing Cat Simulators. Check and check. Cat Simulators offers 24×7 technical support and has a track record of mobile travel.

Instructors believe one of the most important things they have witnessed is the students learning the Cat Simulators Walkaround (the simulated pre-operation inspection based on the same walkaround that all operators must conduct before a shift on an actual worksite). The students are able to identify a huge amount of defects and can actually name the machine parts. Instructors believe this is beneficial when it comes to real life work sites where the operator is able to identify the faulty part on their cry sheets (a.k.a. defect reports).

Instructors also cite the ability for students to practice over and over again until they get the technique right as the next most valuable attribute of Cat Simulators. For example, the trenching application can be practiced without having to backfill and repeat in loose soil. The training is consistent every time, for every student, no matter what the weather is like or the time of day. Finally instructors call out the scenarios themselves as just long enough for students to grasp what needs to be done and short enough to repeat several times until they get it right.

Instructors share that as students move to the iron, they feel that the transfer from the simulator to the actual piece of equipment is “flawless.” For example, when operating the actual Articulated Truck, they find that the oscillating hitch, maneuverability and everything else feels exactly the same. The students’ only complaint? The simulators don’t smell the same as the actual heavy equipment!

It’s a good tradeoff for all of the fuel and maintenance savings Cat Simulators provide.