INVEST IN

TRAINING

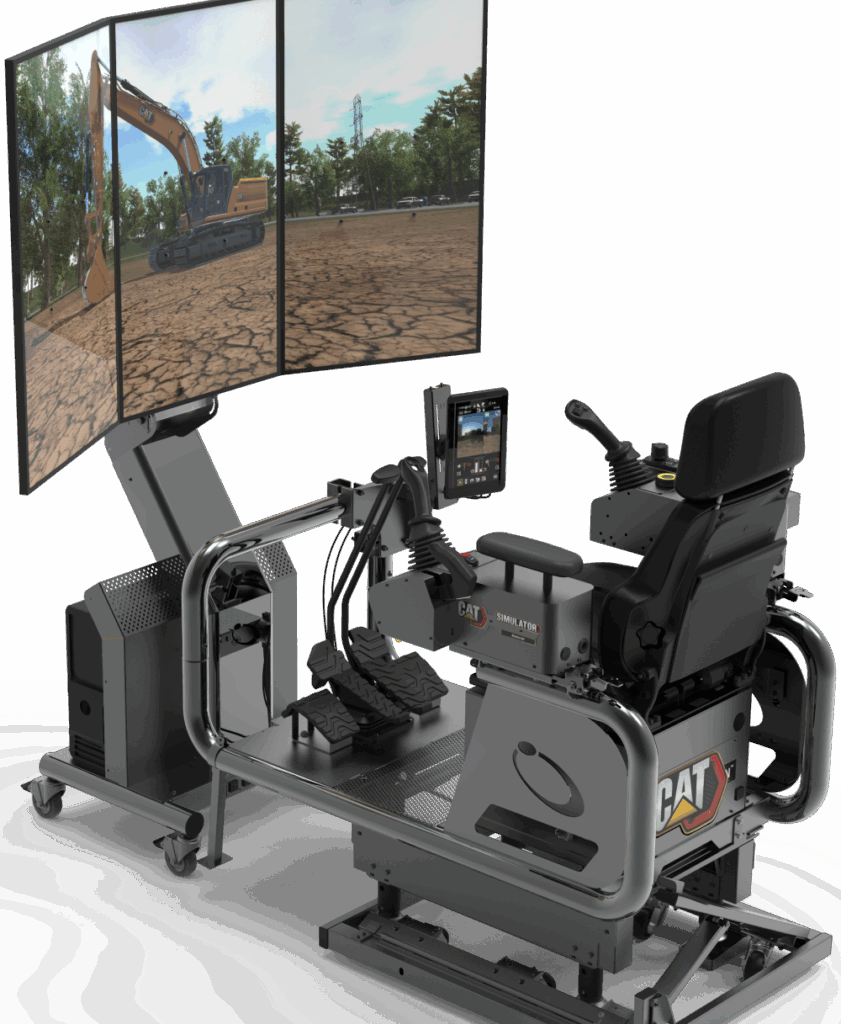

Full Simulators

Each simulator is built with the expertise of Caterpillar subject-matter experts.

SimLite Simulators

A compact, portable training solution for heavy equipment operators.

VR Training

Train in more locations with portable Cat® Simulators VR training experiences.

Read what Clients Say about Cat® Simulators

"Watching how easily learners transition to the actual machine is amazing. It is 100 percent easier for them because of the authentic Cat® controls. One of the things they say right away when they sit down in the excavator is, ‘This is the same as I've been doing on the simulator.'"

Adam RyallsEducation Technology Coordinator

"We have students who are currently in the field working who said that without learning on Cat Simulators and with SimScholars curriculum, they don't know how they would have been hired in the jobs they have now. The Cat Simulators made everything so much easier. And because of SimScholars, students understand why they're doing what they're doing when they operate the equipment."

Tom BrodnaxHEO Instructor

“I had an operator who had never been in a motor grader seat,” recalled Hoskins. “Motor grader cabs are close quarters, so I had him practice on the simulator. When he went out into the field, he was able to maneuver around and use the controls while I stayed on the ground with a two-way radio to instruct him. We were both safer because I wasn’t in the cab with him.”

Harold HoskinsTechnical Trainer

"The support we've received is overwhelming. We, being new last year using the simulators, may have had a few glitches. One phone call, pretty much within a few hours, and somebody helped us work through our problem. We got things straightened out and got our machines back online. I don't think we missed a day of training because we had a technical issue with a machine."

John WalravenHEO Instructor

"The muscle memory the students gain during the five months of training on the simulators’ controls is the same as when they sit down in the real machine’s seat."

Michael StatonAssociate Director

"Students had a lot of experience in training on the simulators and had a little bit of experience on the excavator. They felt it was a lot easier to perform with that real machine. So they really enjoy it and are ecstatic that they can actually operate it and feel confident in themselves.”

Michael DenaroHEO Instructor

“The Cat® Sim program is very immersive-that is the best thing about it. If the simulator doesn’t have the motion platform, it isn’t the same experience. Motion means it feels like you are digging a hole, pushing dirt or picking up a log.”

Michael BuddCareer & Technical Education

“If there's a safety incident, we have the team member spend time on one of our Cat Simulators to learn what went wrong and what can be done differently moving forward.”

Katie PageDirector of Team Development

"If a person did 1,000 evaluations and training with 1,000 operators, that’s a lot of equipment, hourly rates and fuel costs. That really benefits and utilizes the simulator because you’re not tying up the equipment. You just need the operator and his time. You’re not wasting that fuel. And you’re more environmentally friendly."

Jason LakeManager of Heavy Equipment Training